Product search results (25)

-

MAS - Back

Product: Erected carton More about the product »Manual aggregation station (MAS) - Back camera

- Aggregation Carton to Case

- Machine configured for manual cartons inserting into case. Cartons and cases are linked in parent – child relationship

- Ergonomic user friendly machine for easy manual operation

- Equipped with camera system for taking an image of cartons

- Large reading surface for quick, easy capture of codes 400 x 200 mm (optional also other capturing area)

- Pre-arranged for majority of thermal transfer printers (Zebra, Datamax, SATO, etc.)

- Equipped with scanner for parent label reading

- User interface for managing all components through touch screen monitor

- 21 CFR part 11 compliant

- Data exchange with line controller

-

PV-500 (PV)

Product: Erected carton Solution: Print and verify More about the product »Print & Verify 500

- For cartons

- 2D code (Datamatrix) and human readable data printing

- OCR, OCV and 2D code verification system

- Compact size – only 500 mm long in line length

- Speed up to 60 m/min

- Capacity up to 400 boxes/min

- Possible printing technologies: thermal inkjet, continuous inkjet, laser printing

-

MAS - Top

Product: Erected carton More about the product »Manual aggregation station (MAS) - Top camera

- Aggregation Carton to Case

- Machine configured for manual cartons inserting into case. Cartons and cases are linked in parent – child relationship

- Ergonomic user friendly machine for easy manual operation

- Equipped with camera system for taking an image of cartons

- Large reading surface for quick, easy capture of codes 600 x 400 mm (optional also other capturing area)

- Pre-arranged for majority of thermal transfer printers (Zebra, Datamax, SATO, etc.)

- Equipped with scanner for parent label reading

- User interface for managing all components through touch screen monitor

- 21 CFR part 11 compliant

- Data exchange with line controller

-

BTS-RF3 1000 V - blister feeder

Product: Blister Solution: Verify More about the product »Blister transport system - Rotation feeder 1000

- For cutted blisters

- In line or off line transport

- Camera verification

- Rejection of non-positive verified blisters

- Adjustable feeder geometry to blister and tray dimensions

- Precise guide and accurate transfer

- Capacity up to 200 blisters/min

-

SA-CP

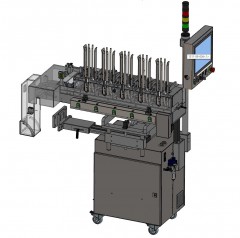

Product: Erected carton More about the product »Semi-automatic case packer with build-in aggregation (SA-CP)

- Aggregation Carton to Case

- Machine configured for automatic cartons inserting into case. Cartons and cases are linked in parent – child relationship

- Ergonomic user friendly machine for easy semi-automatic operation

- Equipped with camera system for taking an image of cartons

- Large reading surface 600 x 400 mm for quick, easy capture of all codes (optional also other capturing area)

- Pre-arranged for majority of thermal transfer printers (Zebra, Datamax, SATO, etc.)

- Equipped with scanner for parent label reading

- User interface for managing all components through 15"touch screen monitor

- ERP/MES data transfer

- 21 CFR part 11 compliant

- Data exchange with high level system

- Integration into different Track & Trace plant level solutions is possible

- Data exchange with line controller

Options:

- Capturing area of 600 x 400 mm (or other)

- Positioning of aggregation label printer to left of right machine side (depending on available space)

- Pallet aggregation

- Other options and modifications available on request

-

BTS-SF 1000 V - blister feeder

Product: Blister Solution: Verify More about the product »Blister transport system – Suction feeder 1000

- For cutted blisters

- In line or off line transport

- Camera verification

- Rejection of non-positive verified blisters

- Adjustable feeder geometry to blister and tray dimensions

- Precise guide and accurate transfer

- Capacity up to 200 blisters/min

- Unloading of blisters with spiral counting wheel

-

PV-600 (PV, CW)

Product: Erected carton Solution: Print and verify, Weighing More about the product »Print & Verify 600

- For cartons

- 2D code (Datamatrix) and human readable data printing

- OCR, OCV and 2D code verification system

- Checkweigher

- Compact size – from 950 mm long in line length

- Speed up to 60 m/min

- Capacity up to 300 boxes/min

- Possible printing technologies: thermal inkjet, continuous inkjet, laser printing

-

PV-1300 (PV, VIG, TE)

Product: Erected carton Solution: Vignette labeling, Tamper evident labeling, Print and verify More about the product »Print & Verify 1300

- For cartons

- 2D code (Datamatrix) and human readable data printing

- OCR, OCV and 2D code verification systems

- Vignette / bollini label application

- Tamper evident label application

- Compact size - only 1345 mm long in line length

- Main flighted transport conveyer belt for accurate carton box transportation

- Possible printing technologies: Thermal inkjet, CO2 industrial laser

-

PV-1800 (PV, VIG, TE, CW)

Product: Erected carton Solution: Print and verify, Weighing, Tamper evident labeling, Vignette labeling More about the product »Print & Verify 1800

- For cartons

- 2D code (Datamatrix) and human readable data printing

- OCR, OCV and 2D code verification systems

- Vignette / bollini label application

- Tamper evident label application

- Checkweigher

- Compact size - only 1850 mm long in line length

- Main flighted transport conveyer belt for accurate carton box transportation

- Possible printing technologies: Thermal inkjet, CO2 industrial laser

-

PV-FCS (PV, VIG)

Product: Flat carton Solution: Print and verify, Vignette labeling More about the product »Print & Verify – Flat carton system

- For flat carton

- 2D code (Datamatrix) and human readable data printing

- OCR, OCV and 2D code verification systems

- Vignette / bollini label application

- Off-line operation with feeder and accumulation conveyor belt

- Speed up to 60 m/min

- Capacity up to 400 flat carton boxes/min

- Possible printing technologies: thermal inkjet, continuous inkjet, drop on demand, laser printing

-

PV-BP (PV)

Product: Blister Solution: Print and verify More about the product »Print & Verify – Blister printing

- For cutted blisters

- 2D code (Datamatrix) and human readable data printing

- OCR, OCV and 2D code verification systems

- Off-line operation with feeder, stacker and accumulation conveyor belt

- In-line operation with adequate blister transport system speed up to 60 m/s

- Speed up to 30 m/min

- Capacity up to 200 blisters/min

- Possible printing technologies: drop on demand

-

LPV - Print and rewind (PV)

Product: Labels Solution: Print and verify More about the product »Label Print & Verify – Print and rewind

- For labels on roll

- 2D code (Datamatrix) and human readable data printing

- OCR, OCV and 2D code verification systems

- Automatic negative verified labels peel-off

- Speed up to 60 m/min

-

Automatic CAS

More about the product »Automatic case aggregation station

- 2D code (child) inspection and verification (layer per layer) integrated in upstream case packer machine

- Linking case with inserted cartons in parent-child relationship

- Print and apply system for printing and labeling parent code on cases (label position according to customer requirement)

- Pre-arranged for majority of thermal transfer OEM printers (Zebra, Datamax, SATO, etc.)

- Equipped with camera verification system for applied label on a case (parent aggregation label 2D code verification)

- Transport system for receiving cases out from case packer, applying & verifying aggregation label and redirecting to accumulation or ejection conveyor can be fully customized (regarding to direction and dimension of conveyors) to meet customer requirements and suitably space on line

- Visibility of the production process

- User interface for managing all components through touch screen monitor

- 21 CFR part 11 compliant

- Data exchange with line controller

Options:

- Layer per layer or row per row code capturing

- Custom transport system design (accumulation and rejection conveyor)

- Over the edge/front/top or some other label applying

- Other options and modifications available on request

- Robot for automated pallet aggregation

-

BAS - Bundle aggregation station

More about the product »Bundle aggregation station

- Verification of bundle with all 2D codes included on boxes or bottles in bundle

- Print and apply system for labeling parent code on bundles

- Parent label 2D code verification system

- Linking bundle with included boxes in parent-child relationship

- Speed up to 30 m/min

- Capacity up to 40 bundles/min

- Possible printing technologies: all thermal transfer printers

-

BDS - Blister detray system

More about the product »Blister detray system

- Tray manipulating system for detraying and transport of blisters

- Loading capacity for 12 trays

- Detraying speed up to 150 blisters/min

- Adjustable transport conveyor speed up to 30 m/min

- Height of blisters stack in tray max. 500 mm

- Max. blister size 90 x 145 mm

- Automatic empty tray disposal unit system

- Mechanical and electrical integration to production line

-

PPV - Pouch printing machine

Product: Pouch Solution: Print and verify More about the product »PPV - Pouch printing machine

- System for printing on pouches

- Capacity up to 150 pcs/min

- Adjustable transport/printing speed up to 30 m/min

- Camera Vision system

- Ejection station

- Mechanical and electrical integration to production line

-

Print & Apply - Case

More about the product »Print & Apply system for cases

- Printing in accordance with GS1 and EAN standards

- Numerous different options of case labeler, depends on user requirements

- Label code verification system

- Tamp Blow or Peel-off label applicator

- Full integrated in technological process on line

- Siemens Simatic Controller

- Robust execution

- Possible printing technologies: all thermal transfer printers

-

Print & Apply - Bottle

More about the product »Print & Apply system for bottle

- Printing in accordance with GS1 and EAN standards

- Numerous different options of bottle labeler, depends on user requirements

- Label code verification system

- Possible printing technologies: all thermal transfer printers

-

Print & Apply - Bag

More about the product »Print & Apply system for bag

- Printing in accordance with GS1 and EAN standards

- Numerous different options of bottle labeler, depends on user requirements

- Label code verification system

- Peel-off, Roll-on or Tamp Blow labeler technology

- Capacity up to 7200 labels/hour

- Possible printing technologies: all thermal transfer printers

-

Print & Apply - Pallet

More about the product »Print & Apply system for palettes

- Printing in accordance with GS1 and EAN standards

- Numerous different options of case labeler, depends on user requirements

- Label code verification system

- Tamp Blow label applicator

- Capacity up to 90 palettes/hour

- Possible printing technologies: all thermal transfer printers

-

Booklet feeder

Product: Booklet Solution: Verify More about the product »Booklet feeder

- For booklet control and verification

- OCR, OCV and 2D code verification systems

- Off-line operation with feeder

- Speed up to 60 m/min

- Capacity up to 400 booklets/min

-

BFS - Blow fill seal printing machine

Product: Vial Solution: Print and verify More about the product »BFS printing machine

- System for printing on flags of BFS products

- Capacity up to 150 pcs/min

- Max print and verify area 72 x 140 mm

- Adjustable transport/printing speed up to 30 m/min

- Integration of two Corona Treatment Units

- Integration of RedCube DOD printer and UV dryer

- Camera Vision system

- Ejection station

- Mechanical and electrical integration to production line

-

ACP - Automatic Case Packer

Product: Erected carton More about the product »ACP - Automatic Case Packer

- Compact and fully automated case packing solution

- Ergonomic user friendly machine for efficient operation

- Ready for quick change over, minimum format parts required

- Transport system with case packing, closing and taping unit

- Single wide screen HMI for machine automation and optional aggregation

- Capacity up to 350 cartons / min

(depends on carton and case layouts)

Options:

- Automatic case filling and closing

- Automatic case aggregation:

- INEL Track & Trace system

- automatic label print, apply and verify

- transportation to good and bad product lane

- Automatic palletization (with cobot or robot)

-

Semiautomatic Print & Apply - Bottle

More about the product »Semiautomatic Print & Apply system for bottle

- Printing in accordance with GS1 and EAN standards

- Numerous different options of bottle labeler, depends on user requirements

- The device is portable and can be placed on any desktop

- Suitable for smaller batches

- Possible printing technologies: all thermal transfer printers

-

Mineral water - Track & Trace

Solution: Verify, Print and apply More about the product »Mineral water - Track & Trace

- Bottle automatic serialization with printed labels

- Bundle (with bottles) automatic aggregation

- Pallet (with bundles) automatic aggregation inside palletizer

| Show all |

Information

INEL, industrijska elektronika, d.o.o.

L: Bukovžlak 105, 3000 Celje

T: +386 (0)3 4264470

F: +386 (0)3 4264477

E: info@inel.com

Invoicing: invoice@inel.com

Orders: order@inel.com

Sales: sales@inel.com